December 5, 2021

Something hanging around on your ceiling you’d rather not look at? Cover it up with a beam wrap… like a hat on a bad hair day.

We have a few options to go through… So, hang on to your hat!

We offer pre-assembled beam wraps, un-assembled components and raw material that you can customize. Let me share our thoughts on these options.

Preassembled beam wraps:

Can be made using new or reclaimed wood, pre-finished or un-finished

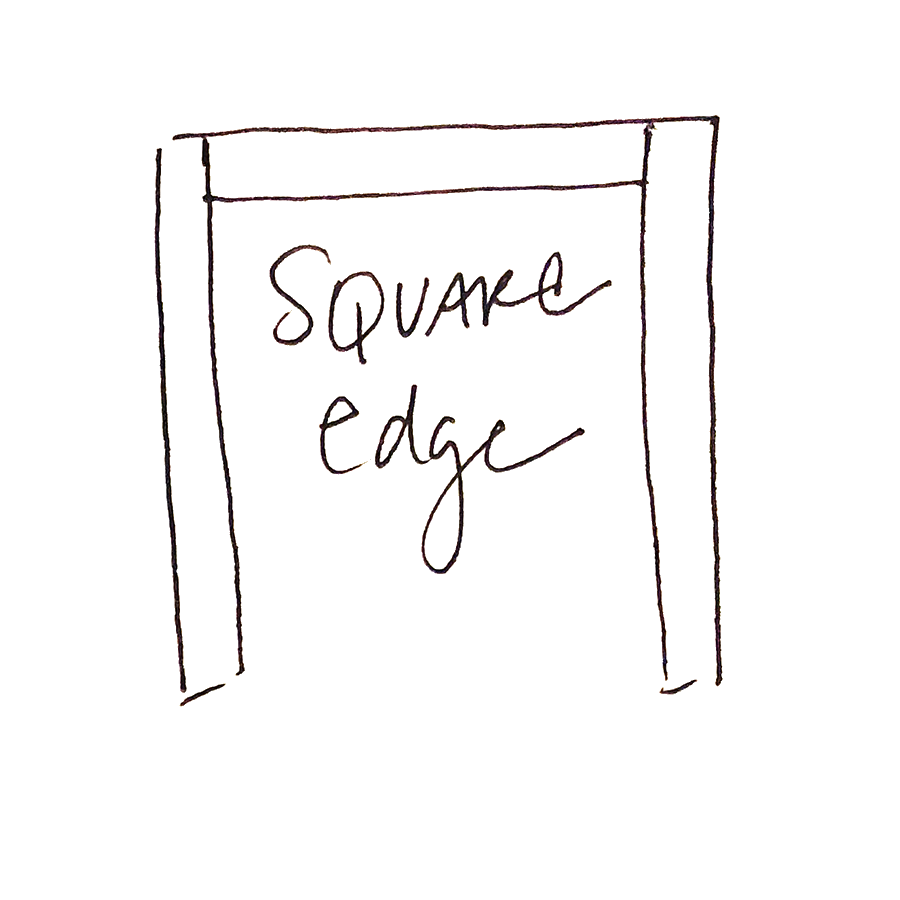

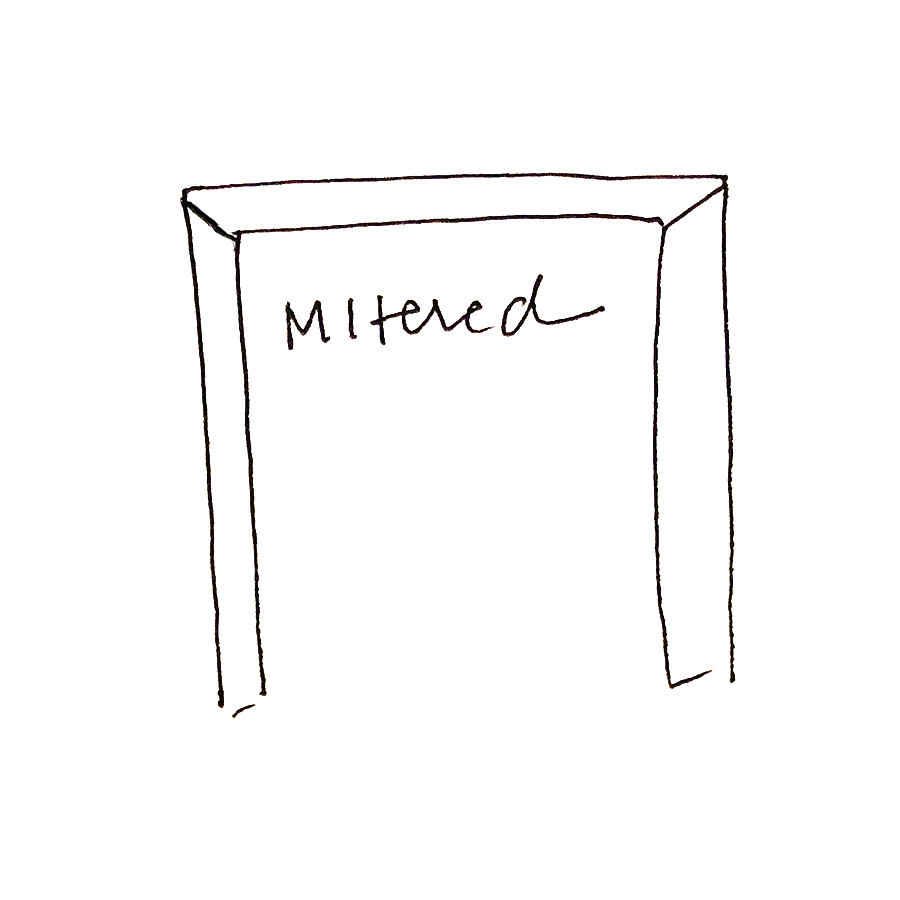

Options: lock mitered, mitered, square edge

Lock Mitered

- Best option for pre-assembled beam wraps

- Looks most like a real beam

- Most difficult to execute. Tricky to mill, difficult to assemble.

- It’s best to use new smooth milled high-quality wood because thin edges are delicate and can be brittle

- Can be made with old face reclaimed material or new material with texture (ex. band sawn) but in order to look its best edges much line up precisely, which does not happen easily with textured wood. This can be time-consuming. It’s possible, but not practical.

- Cannot be modified easily on-site

- Can be difficult to handle and install

Square Edge

- Easiest to make and assemble

- Great for reclaimed wood and new wood with texture

- Can blend seams more easily when using reclaimed wood

- Can offer old edges to help with consistency of appearance

Mitered

- similar to lock mitered, but less difficult to mill and assemble

- great option for pre-assembled beam wraps

- Looks like a real beam

- It’s best to use new smooth milled high-quality wood because thin edges are delicate and can be brittle

- Can be made with old face reclaimed material or new material with texture (ex. band sawn) but in order to look its best edges much line up precisely, which does not happen easily with textured wood. This can be time-consuming. It’s possible, but not practical.

- Cannot be modified easily on-site

- Can be difficult to handle and install

Beam wrap Components, to be assembled on site:

- Our most popular option

- The contractor or homeowner specifies the species, quantity, sizes, and style needed and we make them to order.

- We have the best outcomes with square edge material in this case because the lock mitered or mitered boards can be difficult to assemble and those edges are delicate.

- Square edge boards are adaptable, easy to work with, and fit together nicely for a trouble-free install.

- Most contractors oversize the boards a little to allow for expansion and contraction of the material you are wrapping. This can help to prevent the seams from opening.

- Be sure to account for covering the thickness of the bottom piece by the side pieces and tell us if you need old edges.

The first image shows the customer holding a sample board up prior to installation. In the next image, the beams are almost done and you can see what’s being covered and in the last image, you can see our pine components that were pre-milled and pre-coated with square edges. The customer assembled and installed the pine and did a great job!