Shiplap

Shiplap is one of the most popular profiles flowing through our shop for both interior and exterior design… for good reason! Shiplap siding and paneling is durable, versatile, and easy to work with. With the ability to be installed vertically, horizontally, and diagonally, shiplap meets the criteria for multiple different design looks.

Generally, when people think of shiplap they conjure up images of tranquil white painted pine wall paneling.

Technically shiplap refers only to the shape we mill the wood into. Shiplap can be milled in any wood species in any reasonable dimensions. It can be made from new or reclaimed wood. Our kiln dried wood can be milled smooth, rough or skip planed.

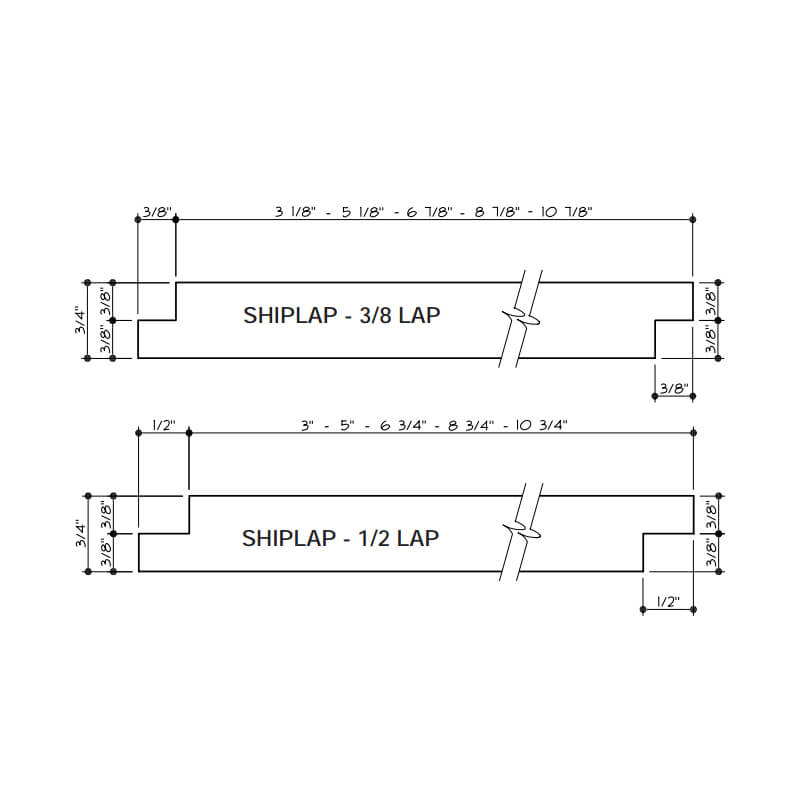

Standard nominal sizes are available (see diagram for actual face sizes). We can also mill custom sizes.

Excelsior’s factory coatings department can apply primer, paint, stain, oil, and polyurethane to your shiplap. Let us do the hard work and save you some time and money.

Connect With UsFAQS

The Janka Hardness Test measures how many pounds of force it takes to embed a .444” steel ball halfway into a piece of wood. This is helpful in determining if a wood specie is suitable for flooring. Harder wood species have higher numbers. Red Oak is our industry-standard for comparing different species. It has a Janka rating of 1290. Most hardwoods and many types of softwood are suitable for use as flooring, especially with proper install, coatings, and maintenance. Please note that all wood will dent with a forceful enough impact.

An example from Hypertextbook.com:

"Humans will only have one foot on the ground while walking. Estimate that the area of the heel on a man's shoe is 10in². When he walks, a 200 lb. man exerts 20 psi because the weight is supported momentarily by the heel. A 100 lb. woman exerts many more psi when she wears heels. Depending on the area of the heel, she can exert as much as 1600 psi under a 'stiletto heel' ¼ inch on a side. This explains why people with wood floors don't want women walking on them in high heels.”

We believe in solid wood flooring because we’ve witnessed how well it performs, especially when compared to engineered wood flooring. We only mill solid wood flooring.

When making solid wood flooring lumber comes straight from the tree, and then it is milled into your flooring. Simple right? Engineered wood flooring is made of layers. Generally, the base layer is made of wood particles bonded together with glue. The top layer is a thin piece of wood affixed to the base with adhesive.

Solid wood flooring is 100% wood. There are no chemical additives that will off-gas into your home. The top layer can’t de-laminate or de-bond because it has naturally bonded itself together. Manufacturing shortcomings such as areas of missing glue or low bonding pressure can’t affect solid wood. Sometimes engineered flooring has a tongue that doesn’t match the color of the face of the flooring. So, when the floorboards gap, a plywood colored strip shows between the seams.

Our solid wood flooring can be repaired, sanded and re-finished many times due to an extra thick wear layer (5/16” thick or 15.8 mm), unlike engineered flooring. Typical engineered flooring has a 2 – 4 millimeter wear layer. A nickel is 2 mm thick.

Solid wood flooring can last over 100 years when cared for properly. It adds value to homes. It reduces allergens (compared to carpet) and increases air quality (compared to engineered).

Many engineered wood flooring products have limitations on board lengths (6’ and shorter for example). This creates a choppy overall effect with lots of seams. This is not the case with our solid wood floors. Often, our average board length is 6’-8’.

While there are circumstances where engineered wood may perform better, please be aware that there is a class-action lawsuit against one of the largest suppliers of engineered wood flooring in the United States. Dangerous levels of carcinogenic formaldehyde emit from this flooring. Please do your homework and choose carefully.

- Wood is sterilized and insects are killed during this process. While some reclaimed wood is quite dry we must take this step to ensure that insects will not be moving into your home.

- Kiln dried wood absorbs coatings better. In fact, coatings will last longer.

- Kiln drying wood decreases shrinkage and movement in service. Non-kiln dried wood may shrink and de-form as it loses moisture from its environment.

Decreased weight makes for easier handling and installations.

Note: There is no way to prevent wood from absorbing water and releasing water into its environment. Trees are designed to drink water and this property can’t be completely diminished. Kiln drying is an important step in reducing (not eliminating) movement in your floors.

Upon inquiry, we will provide a written quote for approval and acceptance. Please review the quote carefully and verify that all quantities, species, sizes are what you ordered. The written quote must be signed and the required deposit must be received by Excelsior to initiate the order.

Be sure to properly store and acclimate your siding and decking at the job site.

Proper storage of your exterior wood products is critical for a successful installation. Understanding your job site conditions and how they impact wood products is essential in determining proper storage methods.

The wood should be kept dry. The goal is to keep the product from direct exposure to the elements (sun, rain, sleet, snow, etc.) prior to installation while allowing it to acclimate. Be advised that your product must also be protected from the ground below and its detrimental effects of moisture infiltration.

Failure to properly store your material can and likely will result in the manifestation of many damaging effects. Proper on-site storage is not Excelsior Wood Products’ responsibility.

Here are some tips to consider that could help keep your siding and decking in good condition prior to installation:

- Keep the wood products elevated off the ground a minimum of 4″-6″ on a flat surface.

- Place a moisture barrier, like a tarp, on the ground beneath the pack.

- Cover the unit with a moisture barrier. Elevate the center so water doesn’t pool on the top.

- Do not completely seal the bundle. Air should be able to circulate fully around and throughout the stack. The goal is for the material to acclimate to the temperature and humidity of the job site. Generally speaking, in our region most wood products are ready to install when they are below a 15% moisture content.

- For best air circulation and acclimation sticker each layer.

- If your siding or decking is pre-coated be careful that you do not get sticker marks on the faces of the boards. In this case, you could stack a layer face to face leaving the slip sheets (thin plastic sheets separating the boards) between the boards so they do not adhere together causing sticking and peeling. Be sure to protect the exposed faces of the boards, even if it is not pre-coated.

In any case, if your order has slip sheets, we encourage you to leave these between the boards until you are ready to install. They will help the boards from sticking together and peeling off the coatings.

The Janka Hardness Test measures how many pounds of force it takes to embed a .444” steel ball halfway into a piece of wood. This is helpful in determining if a wood specie is suitable for flooring. Harder wood species have higher numbers. Red Oak is our industry-standard for comparing different species. It has a Janka rating of 1290. Most hardwoods and many types of softwood are suitable for use as flooring, especially with proper install, coatings, and maintenance. Please note that all wood will dent with a forceful enough impact.

An example from Hypertextbook.com:

"Humans will only have one foot on the ground while walking. Estimate that the area of the heel on a man's shoe is 10in². When he walks, a 200 lb. man exerts 20 psi because the weight is supported momentarily by the heel. A 100 lb. woman exerts many more psi when she wears heels. Depending on the area of the heel, she can exert as much as 1600 psi under a 'stiletto heel' ¼ inch on a side. This explains why people with wood floors don't want women walking on them in high heels.”

We believe in solid wood flooring because we’ve witnessed how well it performs, especially when compared to engineered wood flooring. We only mill solid wood flooring.

When making solid wood flooring lumber comes straight from the tree, and then it is milled into your flooring. Simple right? Engineered wood flooring is made of layers. Generally, the base layer is made of wood particles bonded together with glue. The top layer is a thin piece of wood affixed to the base with adhesive.

Solid wood flooring is 100% wood. There are no chemical additives that will off-gas into your home. The top layer can’t de-laminate or de-bond because it has naturally bonded itself together. Manufacturing shortcomings such as areas of missing glue or low bonding pressure can’t affect solid wood. Sometimes engineered flooring has a tongue that doesn’t match the color of the face of the flooring. So, when the floorboards gap, a plywood colored strip shows between the seams.

Our solid wood flooring can be repaired, sanded and re-finished many times due to an extra thick wear layer (5/16” thick or 15.8 mm), unlike engineered flooring. Typical engineered flooring has a 2 – 4 millimeter wear layer. A nickel is 2 mm thick.

Solid wood flooring can last over 100 years when cared for properly. It adds value to homes. It reduces allergens (compared to carpet) and increases air quality (compared to engineered).

Many engineered wood flooring products have limitations on board lengths (6’ and shorter for example). This creates a choppy overall effect with lots of seams. This is not the case with our solid wood floors. Often, our average board length is 6’-8’.

While there are circumstances where engineered wood may perform better, please be aware that there is a class-action lawsuit against one of the largest suppliers of engineered wood flooring in the United States. Dangerous levels of carcinogenic formaldehyde emit from this flooring. Please do your homework and choose carefully.

- Wood is sterilized and insects are killed during this process. While some reclaimed wood is quite dry we must take this step to ensure that insects will not be moving into your home.

- Kiln dried wood absorbs coatings better. In fact, coatings will last longer.

- Kiln drying wood decreases shrinkage and movement in service. Non-kiln dried wood may shrink and de-form as it loses moisture from its environment.

Decreased weight makes for easier handling and installations.

Note: There is no way to prevent wood from absorbing water and releasing water into its environment. Trees are designed to drink water and this property can’t be completely diminished. Kiln drying is an important step in reducing (not eliminating) movement in your floors.

Upon inquiry, we will provide a written quote for approval and acceptance. Please review the quote carefully and verify that all quantities, species, sizes are what you ordered. The written quote must be signed and the required deposit must be received by Excelsior to initiate the order.

Be sure to properly store and acclimate your siding and decking at the job site.

Proper storage of your exterior wood products is critical for a successful installation. Understanding your job site conditions and how they impact wood products is essential in determining proper storage methods.

The wood should be kept dry. The goal is to keep the product from direct exposure to the elements (sun, rain, sleet, snow, etc.) prior to installation while allowing it to acclimate. Be advised that your product must also be protected from the ground below and its detrimental effects of moisture infiltration.

Failure to properly store your material can and likely will result in the manifestation of many damaging effects. Proper on-site storage is not Excelsior Wood Products’ responsibility.

Here are some tips to consider that could help keep your siding and decking in good condition prior to installation:

- Keep the wood products elevated off the ground a minimum of 4″-6″ on a flat surface.

- Place a moisture barrier, like a tarp, on the ground beneath the pack.

- Cover the unit with a moisture barrier. Elevate the center so water doesn’t pool on the top.

- Do not completely seal the bundle. Air should be able to circulate fully around and throughout the stack. The goal is for the material to acclimate to the temperature and humidity of the job site. Generally speaking, in our region most wood products are ready to install when they are below a 15% moisture content.

- For best air circulation and acclimation sticker each layer.

- If your siding or decking is pre-coated be careful that you do not get sticker marks on the faces of the boards. In this case, you could stack a layer face to face leaving the slip sheets (thin plastic sheets separating the boards) between the boards so they do not adhere together causing sticking and peeling. Be sure to protect the exposed faces of the boards, even if it is not pre-coated.

In any case, if your order has slip sheets, we encourage you to leave these between the boards until you are ready to install. They will help the boards from sticking together and peeling off the coatings.